Mains power supply : 230 V – 50/60 Hz

Microprocessor control

Control accuracy ±2 %

Control for soldering iron of 17 W à 450 W and for solder pot PE 500

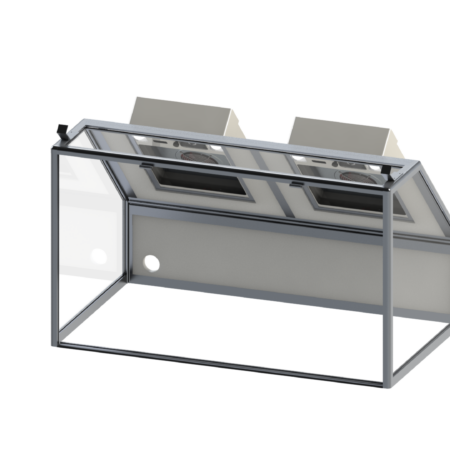

RP500 Power regulator

115.00 € HT

OPERATING PRINCIPLE OF REGULATOR : réf 1010001077

The regulation is completely electronic and reliable. A system with microprocessor was studied to confer on this case of the functions almost equivalent to a system of thermoregulation for iron to incorporated sensor.

The principle consists in regulating open-loop soldering irons from 17 to 450 W from the potentiometer situated on the case-grip. According to the position of the potentiometer the iron is fed by wave trains to obtain the wished power.

The microcontroller is synchronized in the sector what allows a not random switching 0 volts to avoid any interference. Because of his open-loop functioning, the microprocessor calculate the value of the returnable power and the time which it will be necessary to reach him. During this optimized lapse of time, the microprocessor will schedule automatically the necessary wave trains to accelerate the stoking.

Thanks to this system of integrated calculations, 100 % of the power is scheduled during the starting up. Once the time past, the iron will take back its power of instruction. This principle of functioning takes place in the starting up or in every positive change of the potentiometer (increase of the value of instruction of the temperature). Also for any negative change of the value of instruction (decrease of the temperature), the microprocessor according to the value of the returnable power, calculates the time which it will be necessary to affect it. The supply of the iron will then be totally arrested to allow the iron to arrive more quickly at its value of instruction. The blinking of the light indicates in real time the supply of the iron.

USE WITH THE PE500 TIN POT: The power regulator is positioned between the 230 V mains socket and the PE500 power cord. It allows the power of the bath to be modulated between 0 and 100% in order to obtain the alloy temperature suitable for the application in play.

Frequently bought together

Other recommended products

78 Rue Raymond Poincaré

92000 Nanterre – FRANCE

Tél. +33(0)1 40 86 00 09