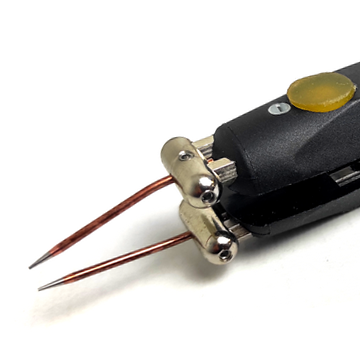

ESI1R Electrodes for Joule soldering

For SI1R

Principle:

Electric resistance welding, also called Joule effect welding, is a technique that replaces traditional soldering with a soldering iron. Its advantage is that it provides instant localized heat. The principle is to pass a powerful current at very low voltage through a contact resistance at the point of application. The law which explains this phenomenon is the Joule effect: W = RI² t

Use and advantages:

The welding operation consists of pinching the parts to be assembled and adding a tin alloy. As soon as the pedal is engaged, the temperature instantly rises to the desired temperature (maximum 1100 ° C).

- Better heat distribution (= better weld distribution)

- No component overheating (= instantaneous welding up to 1100 ° c) and therefore reduces thermal damage

- Flameless process

- Speed of execution

- The pliers holds the assembly and leaves one hand free for welding

- No keeping a heating tool on standby

- Allows access to restricted areas

- Reduces energy consumption compared to a traditional heating tool

- Low maintenance and upkeep: the electrodes last longer than soldering iron tips and do not require tinning

Applications :

Connector soldering on semi-rigid

Coaxial connector center contact solder

Welding of several strands at the same time

Soldering of multi-pin connectors

Soldering sensitive connections

Welding high frequency cables

Butt splicing of copper strips

Fast welding of pre-tinned pellets

ESI1R – Set of 5 pairs of copper-plated stainless steel electrodes

ESI1P – Set of 5 pairs of flat stainless steel electrodes

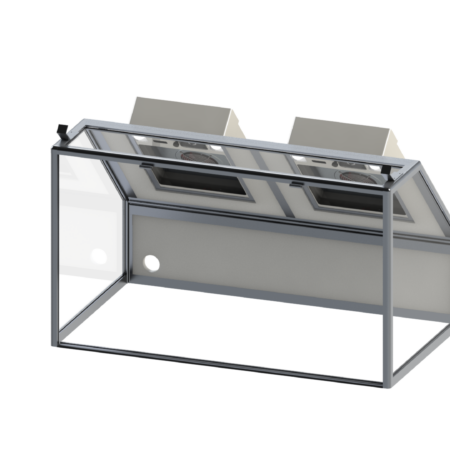

Frequently bought together

Other recommended products

78 Rue Raymond Poincaré

92000 Nanterre – FRANCE

Tél. +33(0)1 40 86 00 09